Superseal Fittings – SM & SI Range

– Specifications

All our technical information for our Superseal SM & SI Range of products can be found here.

Superseal Fittings – SM & SI Range

Style and Description

For Use With Stainless Steel Tube

Superseal is a special fitting designed to provide extra grip on hard steel, stainless steel and other polished metal pipe.

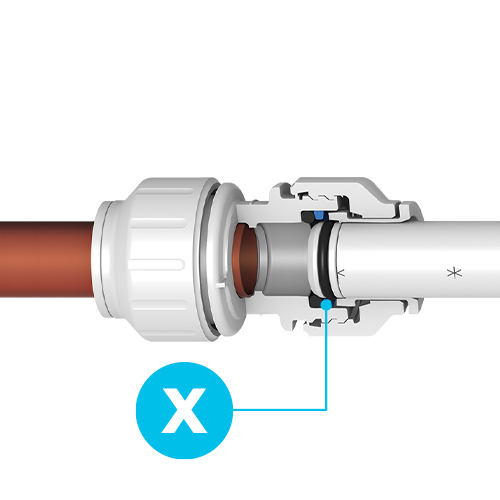

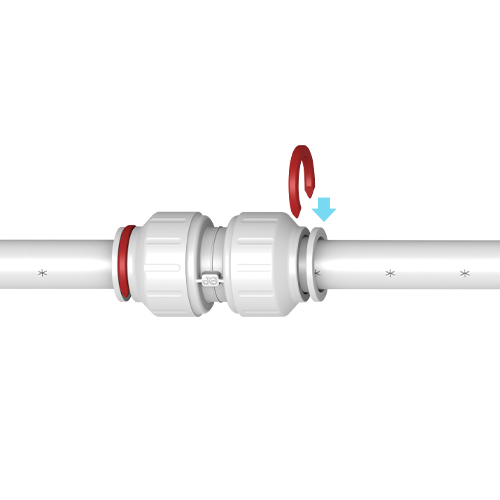

The Superseal design features a collet with integrally moulded stainless steel teeth, similar to the standard Speedfit design, but incorporating an additional hand-operated nut and wedge shaped plastic washer to apply extra pressure to the collet, and the double O-Ring seals. This ensures that the collet teeth bite thoroughly into the tube to provide grip while at the same time, compressing the O-Rings to further enhance sealing.

Like other John Guest fittings, Superseal fittings are suitable for potable liquids and other food quality applications.

Media / Application

✓ Potable Liquids

✓ Air / Vacuum

Sizes – Outside Diameter (OD) Pipe

- 1/4″

- 5/16″

- 3/8″

Maximum Working Pressure (kPa)

| Temperature | Pressure | |

|---|---|---|

| AIR / VACUUM | 1/4″ & 5/16″ | 3/8″ |

| -20°C | 1600kPa | 1000kPa |

| +1°C | 1600kPa | 1000kPa |

| +20°C | 1600kPa | 1000kPa |

| +65°C* | 1000kPa | 700kPa |

| Temperature | Pressure | |

|---|---|---|

| POTABLE LIQUIDS | 1/4″ & 5/16″ | 3/8″ |

| -20°C | DO NOT FREEZE | |

| +1°C | 1600kPa | 1000kPa |

| +20°C | 1600kPa | 1000kPa |

| +65°C* | 1000kPa | 700kPa |

*NOT to exceed maximum temperature

Installation Instructions

Step 1

Prepare the Pipe

Ensure the pipe is free of score marks. Cut the pipe square. We recommend the use of JG Pipe Cutters.

To prevent damage to the O-Ring, remove all burrs and sharp edges. When connecting Speedfit Pipe, use a Speedfit Pipe Insert. A twisting motion will aid insertion. The insert should only be used with Speedfit Pipe.

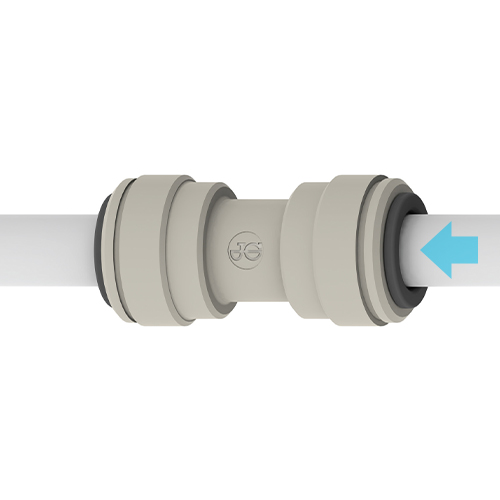

Step 2

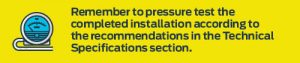

Push Up to Pipe Stop

Push the pipe into the fitting, to the pipe stop.

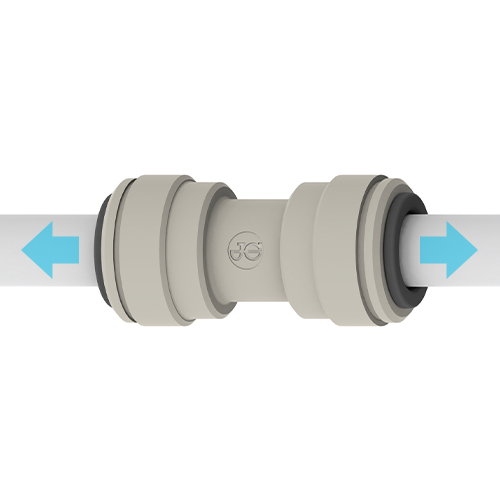

Step 3

Pull to Secure

Pull on the pipe to check it is secure. Test the system before use.

Don’t forget to push the pipe fully into the fitting, past both the collet (gripper) and the O-Ring.

Troubleshooting

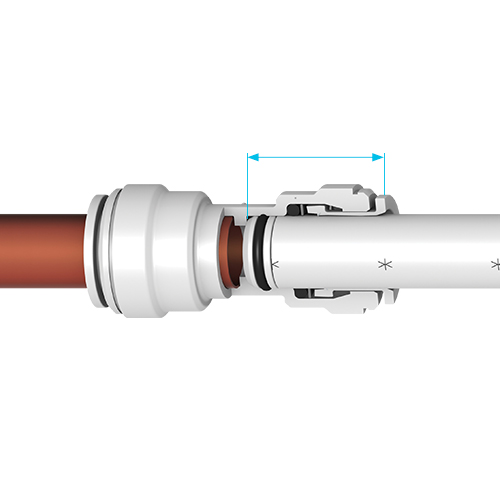

Pipe Stop Distances

Stops are located at the following distances from the end of the fitting:

| Size | Stop Distances |

|---|---|

| 10mm | 20mm |

| 15mm | 30mm |

| 22mm | 35mm |

| 28mm | 44mm |

Check Pipe Grip & Depth

Make sure to push the pipe fully into the fitting, past both the collet (gripper) and the O-Ring.

Fitting may be gripped but not sealed if pipe is not fully inserted.

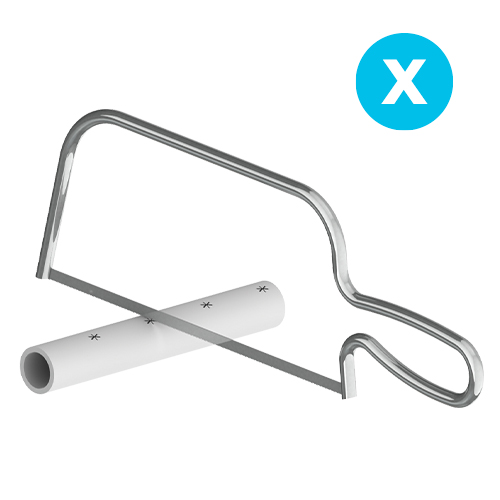

Do not use a hacksaw to cut the pipe.

This will leave unwanted burrs on the end of the pipe.

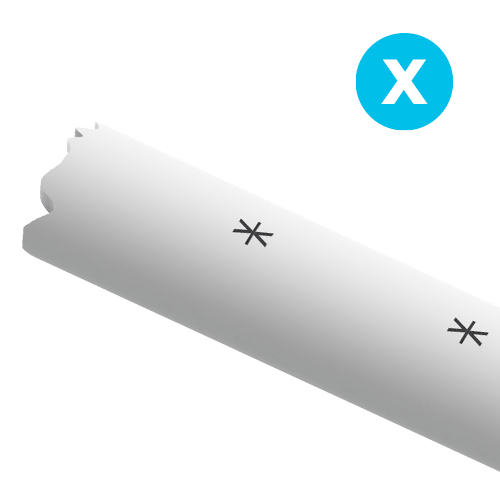

Do not use damage or scored pipe.

Score marks can cause leaks past the O-Ring.

How to Disconnect

Quick Disconnect

Push in Collet and Remove Tube

To disconnect, ensure the system is depressurized, push the collet square against the fitting. With the collet held in this position the tube can be removed.

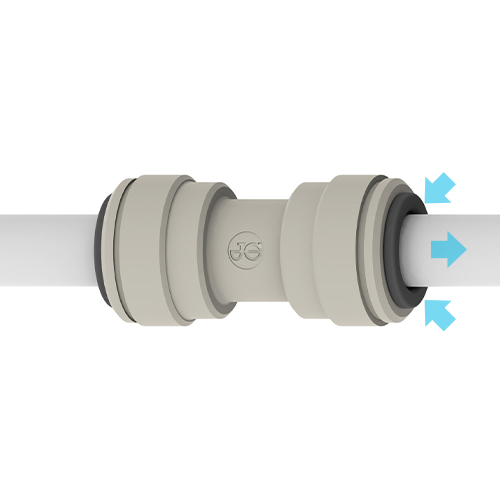

Collet Covers & Clips

Collet Cover & Clip Applications

Use a collet cover or collet clip to provide added security against pipe disconnection, e.g. the fitting coming into contact with rigid surfaces and behind dry-lining walls.

Collet covers for use with standard Speedfit fittings, are available in white, red or blue to allow colour coding of pipes.

White & Grey Collet Clips

White or grey collet clips are used with standard fittings to prevent accidental pipe disconnection.

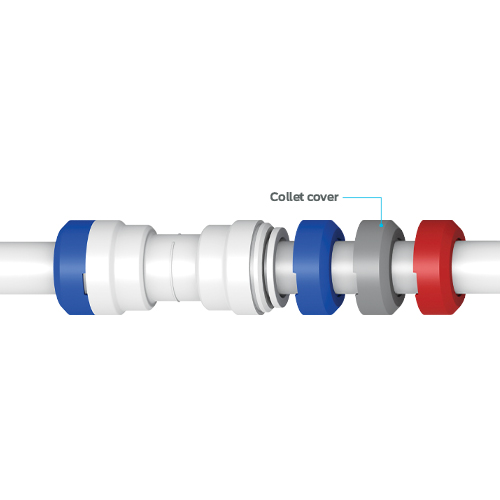

Red & Blue Collet Clips

Red or blue collet clips provide colour coding of pipe on Twist & Lock fittings. They are not designed to prevent accidental release, and should be fitted when the fitting is in the locked position.