How to correctly choose and install the right plumbing pipe

Whether you’re working on a new build bathroom, a retrofitted kitchen or a large-scale commercial build, there are plenty of pipe materials to choose from for your installations. And, with pipes coming in copper, stainless steel, PEX and polybutylene, it can be hard to know what you should be using where.

So, here’s our guide on how to correctly choose and install the right plumbing pipe for your projects.

Where you should be using metal vs. plastic pipes

To choose the right plumbing pipe, one of the first questions you might be asking is whether you should be using plastic or metal pipes. The good news is the answer is fairly straightforward.

If you are surface mounting the pipes, or any other situation where you can see the pipe work, then copper, chrome or stainless steel are often preferred due to the aesthetic finish they offer. Historically, copper pipes have also been the go-to material for internal water supply pipework. But plastic pipe is becoming more common due to its flexibility and durability.

When you are connecting pipework to a boiler, it’s best to use copper pipes. Although plastic pipes do work at tolerances that are suitable for direct connection to a boiler, it's recommended that the first metre of the pipework should be copper to eliminate the risk of corrosion that could be caused by system cleaners or inhibitors. Gas pipework to the boiler should always be installed using copper pipe too.

Both plastic and metal pipes can be used for central heating, but there are benefits of using plastic over copper. When copper heats it expands, and when it cools it recedes, which can lead to air ingress into the system which can create ‘air locks’ and affect heat transfer. The JG Speedfit PEX barrier pipes and JG Layflat polybutylene pipes have a five-layer barrier system which insulates the water so this expansion and contraction only affects the metal fittings attached to the pipe, not the pipe itself, which eliminates the risk of air ingress into the system.

The benefits of plastic pipes

When compared to traditional metal, plastic plumbing pipe comes with many benefits. Here are just the top three:

- It is cheaper than copper: with current figures putting it around a quarter of the price of copper. Plus, you won’t need to buy as many fittings, as longer pipe runs can be made with fewer joints.

- It offers greater flexibility: if you’re working on a complicated job, for example where you are running piping between joists or in the ceiling or round a corner, it is easier to do this work with plastic piping, particularly polybutylene. This is also handy when you’re installing underfloor heating, as polybutylene pipes are easy to loop and doesn’t require the pipe to bend.

- It’s less susceptible to pipe damage: copper doesn’t expand when it freezes, whereas plastic has some flexibility to allow for water expansion, so it is less susceptible to damage during cold weather periods.

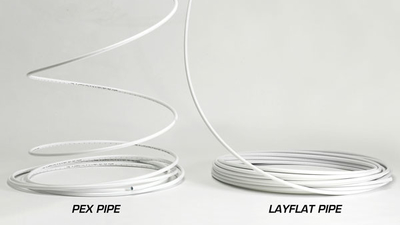

PEX vs. polybutylene: what to use where

Now you know the benefits of plastic plumbing pipes compared to copper, you might be looking to use it for your next project. The next thing to consider is whether you want to use PEX pipes (also known as cross-linked polyethylene) or polybutylene pipes. There are benefits of each, so here’s how to choose the right plumbing pipe:

Where to use polybutylene pipes:

Polybutylene pipes, like JG Layflat polybutylene pipes, come in coils and are designed to bend so you can get it through joists. You can also use it applications where you want a straight run of pipe, so it offers flexibility for all situations.

It is ideal when you are trying to do bends in pipe work, for example when installing underfloor heating, or getting the water supply between rooms. It is also straightforward to install, as it will hold the bend in place where you need it.

If you’re working on a retrofit bathroom or kitchen installation, polybutylene pipes can help when you’re working in small spaces like trying to fit a new dishwasher into a kitchen.

When to use PEX pipes:

Pipes, like the JG Speedfit PEX barrier pipe, are ideal to use when you need a straight run of piping, for example to an appliance. They are also easier when you are trying to feed pipe up a wall like in commercial applications.

You can also use PEX coils for underfloor heating, as it has good insulating properties. However, it is a more rigid material than polybutylene, so in some instances, cold form bends would be needed to hold the pipe in shape.

When running PEX or polybutylene in solid floor applications, you need to use the appropriately sized conduit to ensure that it the pipe is protected from any floor movement caused by thermal expansion. A conduit should also be used in high-risk areas that may be susceptible to damage, as well as through wall piping applications.

Our top four pipe installation tips:

Whether you’re looking to install copper or plastic pipes, we have some top tips to consider when installing plumbing pipes.

- Try to avoid installing pipes in areas that are susceptible to mice or rat attacks. They have a high tensile bite strength that can go through concrete, steel, copper and plastic pipes.

- Make sure that you are using the correct pipe insert for the fitting to ensure a tight seal. Different inserts suit different fittings, so it’s always best to check the product information.

- If you’re installing a plastic pipe through a stud wall, then it’s best to run some foil tape around the pipe. This way you can still use a pipe finder to trace the pipe if you need to once the wall has been finished.

- Our JG Speedfit PEX barrier pipes also comes in both blue and red, so you can use it to show what is hot and cold water supply lines easily.

Support

If you have any more questions on how to correctly choose and install the right plumbing pipe, then please get in touch with our technical team of experts who are always happy to help.