No leak, no problem – Top 5 tips for leakproof push-fit connections

Plastic push-fit fittings have become a tried and tested plumbing and heating solution over the past decades. In fact, regardless of your experience, fitting push-fit should be a quick and easy process. However, despite being a more efficient solution that requires less tools than traditional systems, leaks can still occur if they are not installed correctly.

Considering that 2.4 billion litres of water is lost every day in the UK, it is never a waste of time to double-check each step of a push-fit installation, to ensure you are making a leakproof push-fit connection.

In this blog, we highlight five important tips to make push-fit connections as leakproof as possible. And how, if each installer follows these tips, they will be doing their part in creating more sustainable homes in the process.

1. Keeping systems clean

One of the most common causes of leaky push-fit connections is damaged fittings or pipes. Just as a chef would never use dirty ingredients, an installer should keep their fittings and pipes as clean as possible and free from debris.

The best way to prevent fittings getting dirty or damaged is to keep them sealed in their bags until you need to use them. Similarly, poorly cut or damaged pipes are one of the most common causes of poor or leaky connections. Plastic pipes should always be cut with a specialist plastic pipe cutter, to prevent jagged or sharp pipe ends.

The importance of having clean pipe ends cannot be understated. What is a simple step to include in an installer’s push-fit installation, goes a long way to preventing leaks. If done across the board, this can lead to a more sustainable industry and protect homeowners from costly leaks in the process.

2. Twist & Lock® your way to a leakproof push-fit connection

The Twist & Lock® range from JG Speedfit is a perfect way to doubly ensure that your push-fit connections are as leak-proof as can be. The fittings feature a primary O-Ring seal and a Grip & Seal™ collet with stainless steel teeth, which mean that each connector in the range creates a quick, leakproof push-fit connection that can be swiftly mounted and dismounted, in a flame and tool free manner.

Equally, the fittings’ non-toxic polybutylene construction gives them resistances to corrosion and scale build up, which ensures it is durable and watertight while preventing the need for additional maintenance once installed. When the fittings are used in conjunction with JG Speedfit’s plastic barrier pipes the system will not require flushing as often as a copper alternative, due to the pipes preventing oxygen ingress.

3. Make fewer connections by using plastic pipes

Whilst push-fit fittings, such as those in JG Speedfit’s Twist & Lock® range, can be connected to both plastic and copper pipes, to truly make connections as leak-proof as possible it is always best to use JG Speedfit pipe.

Flexible plastic pipes such as the PEX and Polybutylene pipes from JG Speedfit, can bend around corners and tight spaces, which minimises the need for extra fittings and joints, which in turn reduces the number of spots where leaks can occur and therefore, the amount of maintenance required too.

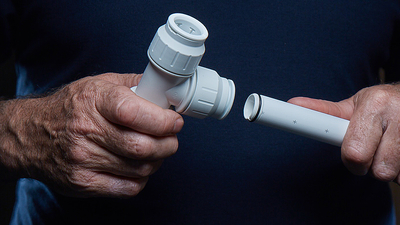

4. Always use pipe inserts when making connections with plastic pipe

When working with JG Speedfit plastic pipes, you will have to use a JG Speedfit pipe insert, which, just like your pipes and fittings, should be kept in safe packaging to remain clean.

Whilst experienced installers will always cut pipes as straight as possible, there are a myriad of reasons why a pipe may slightly lose its shape when cut. JG Speedfit pipe inserts ensure that the end of the pipe is kept nice and round and can minimise any loss of shape that may occur when cutting. To achieve this, it’s important to make sure the insert goes fully into the pipe.

Similarly, inserts allow for a more efficient seal between the outer diameter of the pipe and the O-Ring of the fitting it is being pushed into, by maintaining the structural integrity of the pipework.

JG Speedfit also offers Superseal Pipe Inserts with twin O-Rings, which when used in conjunction with the push-fit fitting’s primary O-Ring creates a unique multiseal that further improves the leakproof push-fit connection.

5. Knowing the problem

It’s always frustrating when leaks do happen. However, when they do it’s best to remain calm and take steps to understand how to prevent further maintenance being required.

Usually, the blame can be put on one of three culprits. Either, the pipe hasn’t been cut properly, the pipe insert hasn’t been fully pushed into the pipe, or the pipe isn’t fully connected to the fitting itself, or a combination of all three.

When you are fixing a connection that is leaking it is vital that you follow your well-trained instinct, and ensure that, upon next installation, everything is kept as clean as possible and that the right tools and equipment are used for the job.

Follow these five steps, and you’ll be making leakproof push-fit connections every time.