How does the demand for purer water affect plumbers?

We all know just how much pipework lurks under the kitchen sink. With so many second fix connections to install appliances/ fixtures such as washing machines, dishwashers, outside tap and more, it can be a busy space.

So, with growing demand for filtered tap water, it raises the question – where will it fit?

For installers fitting water filtration systems, it is key to find out how to fit these systems effectively in the busiest section of pipework in the house.

In-line Water Filters – A new staple of the home

UK’s tap water is amongst the cleanest in the world, but it can often pick up harmless sediment, minerals and impurities that affect its taste. Chlorine impurities and limescale cause the most notable issues for homeowners.

One of the most cost-effective routes to filtered water without taste, taint and odour is to use a quality in-line water filter system. In-line filters offer a simple solution with up to 12 months of service before replacement. They provide approximately 6,000 litres of clean water filtered to 10 microns of physical matter.

Installing these systems doesn’t need to be complex

Installing an in-line filter system under a sink can be tricky, especially when there is already a lot of pipework present.

A simple but effective solution for installers can be the use of multifunctional, push-fit service valves that come in multiple shapes and sizes. They can help reduce installation times by around 40%, which is a huge plus for those who don’t want to spend all day in an uncomfortable position under the sink.

Use Multifunctional Push-Fit valves

A great example of this is the 3-in-1 ASV range of tee connectors, combining a tee, single check valve and shut off valve in one. Instead of installing three separate fittings, you only install one – saving on cost, time and space.

The JG water filtration range is specially designed to enable quick and hassle-free installation and service of in-line filters. The push-fit nature allows the valves to be connected and disconnected without the need for tools. This makes life easier for the installers and removes the need to carry tools underneath the sink where manoeuvrability and visibility is always low.

The filters installed using the JG shut off valves only need a 1/4 turn by hand to open or close the water supply. All fittings and valves manufactured by the company use superior quality and high performing EPDM seals, giving a longer life and less chances of ‘hairline’ cracks or leaks to the product.

LLDPE pipes will solve any under sink issues

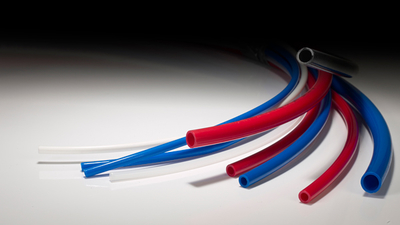

It’s also advised that installers use pipes made from LLDPE (Linear Low Density Polyethylene), to make the connection between the mains supply and the in-line filters.

Soft and flexible, LLDPE pipes are long lasting as they can withstand a wide range of temperatures and pressures. LLDPE pipes also remove the risk of contaminating the water supply, thanks to its chemical compatibility.

Check out the highly engineered LLDPE pipes from John Guest which are compliant with third parties like the FDA and NSF International.

Any installation under the sink can be complicated, because the space is so busy to accommodate any additional fixtures. By utilising the optimal fittings and pipes, the process can be made simple and more efficient than previously thought.