Joist cabling and plastic pipes – The perfect connection

When fitting floors above ground level, wooden joists have been extensively used in the past by those in the construction industry. Copper plumbers have found these to be notoriously difficult to work with despite how cost-effective the wooden joists are. This is where plastic pipes come into their element to provide the perfect connection.

Advances in plastic plumbing technology can overcome the issues brought by joist cabling. By nature, they are more adaptable than their copper counterparts and joist plumbing provides the perfect example as to how their advantages can be seen in everyday construction and plumbing installations.

Wooden joists can bring many hazards

If a plumber is installing copper pipework, holes or notches need to be made in the joists for the pipes to fit in or run through. It can be quite difficult to drill and line up the holes precisely.

When health and safety is considered, alongside inflexible and rigid nature of copper pipes, installation can become incredibly complex, demanding and time-consuming.

Similarly, this type of installation can cause a serious risk of fire – while connecting the copper pipes together with flux solder and a blowtorch. With wooden joists, it’s an accident waiting to happen.

Drilling and notching holes can also seriously weaken the joists, which puts the structural integrity and durability of the floor in danger.

Why modern joists work perfectly with plastic pipes

Modern joists include cores that are easier to drill and some even have additional space for the pipes to run through.

Commonly found on building sites nowadays, the I-Joist (or I-Beam) and Cross Web joists have been engineered with pre-formed holes and knock-out panels. This is where pipes like the JG Layflat® marry seamlessly with modern joists.

This polybutylene pipe comes in easy-to-handle coils of varying lengths and sizes, which simply adapt to the surrounding situations and applications necessary. As it is a more flexible pipe material, it can be bent to run through the holes or notches in long lengths without having to make multiple connections. Moreover, this process is a lot safer and more hygienic than copper installations.

Another advantage of the JG Layflat® pipe is that it is made of five layers, the centre of which is a coloured oxygen barrier that prevents the ingress of air in the system. This ultimately reduces the effect of corrosion on metal components that copper plumbers traditionally experienced.

Overall, the whole installation process is more efficient, safer and productive.

Manifold plumbing is growing

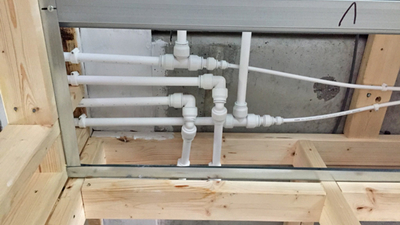

Push-fit manifold plumbing has seen a rise, partly due to the modernisation of joist designs as well as the speed and convenience of plastic plumbing.

Plumbing installers have the choice of running continuous flexible pipes up to a bath or basin, or anywhere a hot or cold point connects. This is because a central manifold position removes the need to have multiple fittings running under the floor or in ceiling spaces. Tidying up the pipework and layout is always a benefit for installers!

A continuous length of pipework also ensures maintenance and leak detection is made easier. In case of a leak, it is only necessary to check the two ends of the pipe, rather than investigating multiple connection points. For installers keen to be cost-effective this is a huge advantage.

Plastic pipes and fittings not only make joist cabling easier, but also guarantee the first fix process is completed to the best possible standard. This also offers a reliable and effective solution for end users, which is the main objective of any job.