Why manifolds using Speedfit technology are the most reliable and efficient

Speedfit Technology is well known in the plumbing industry for delivering reliable, leak-proof connections, that make installations easier, quicker and allow installers to work effectively in tight spaces. Our reputation extends to the Speedfit technology used for manifolds, so what exactly makes them so reliable and efficient? In this blog post, we reveal it all…

It’s all in the design

16mm is considered a standard pipe diameter across Europe, and therefore, manifolds which are imported from a number of overseas sources are usually designed for 16mm pipe diameter. Often the importers have limited understanding of pipe or fittings, and rely on third-party guarantees for the product they sell.

JG Speedfit being a UK manufacturer designs manifolds that are compatible with standard UK pipe sizes. Speedfit manifolds connect directly with 15mm pipe which is the standard pipe size used for domestic plumbing, therefore eliminating the need for additional adapters and connectors.

Designed to fit

Speedfit products are all designed to be very quick and simple to install. Push-fits take all the guesswork out of making watertight joints and ensure a leakproof connection every time. This is as important when connecting pipes to a manifold as it is when connecting pipework to radiators, or appliances to mains water supply during second-fix plumbing. However, manifold plumbing is not always so straightforward.

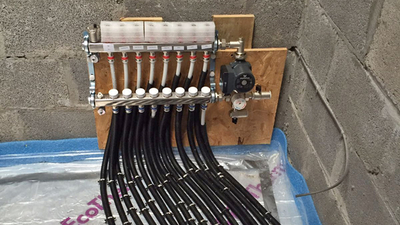

A standard manifold can have up to 24 pipe connections and often they are located in a very small space. Sometimes the manifold is stored in a kitchen cupboard or an additional cupboard must be added for effective installation. This presents a range of potential issues, forcing an installer into a tight space where there is little to no room to even use a spanner. With a JG Speedfit manifold, this is not an issue, as it uses Speedfit push-fit plumbing technology to connect pipes. All you need to do is cut the plastic plumbing Speedfit pipe to length, push it into the manifold collet, and make the connection, without manoeuvring yourself into awkward positions to make difficult joints.

Installers using non push-fit manifolds require additional fittings, such as threaded BSP joints, to connect the manifold to the boiler, whereas JG Speedfit manifolds remove the need for these additional components. Speedfit’s push-fit isolated valves make installations easier, simpler, and a lot more convenient.