JG Speedfit push-fit plumbing & heating

Make fast, simple and secure connections with our push-fit fittings, valves and pipes for plumbing and heating.

Discover our range

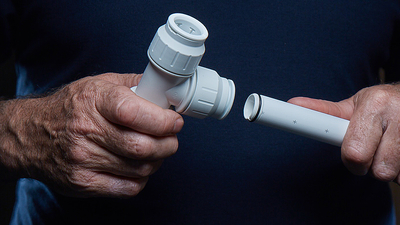

Get fast and leak-tight connections first time, every time, with JG Speedfit’s easy to install push-fit plumbing and heating system. Using a unique blend of push-fit and multi-seal technology, Speedfit can be installed and demounted in seconds without the need for tools or hot works.

From straights, elbows and tees to ultra-flexible pipe, service valves and tap connectors, we have everything you need to complete your job in no time. JG Speedfit is suitable for hot and cold water and central heating systems.

Fittings

Push-fit Valves

Flexi Hoses

Pipes

MDPE Fittings

Accessories

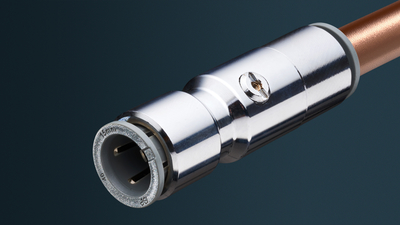

Pioneering push-fit technology

From our pioneering push-fit plumbing and heating system to our latest tool-free service valves and tap connectors, JG Speedfit technology is trusted by millions across the globe.

See inside our unique push-fit and multi-seal technology.

Eager to learn about UFH? Get your free eGuide.

When it comes to underfloor heating, there’s a lot to consider, which is why we’ve created an Installer’s Guide to Underfloor Heating, helping you to navigate the intricacies of every project.

Super fast. Super simple. Super secure.

Whether you are working on a new build or a repair, maintenance or improvement job, you can be sure JG Speedfit will provide an instant leak-tight connection. Our push-fit plumbing and heating system also comes with a 50-year guarantee for extra peace of mind.

High performance leakproof connections

Install, demount and refit in seconds, without tools

Safer and cleaner with no hot works, flux or glue

Less labour-intensive, especially in tight spaces

Non-toxic, resists corrosion and scale build-up

Compatible with plastic or copper pipe

Find a JG Speedfit stockist near you

An icon of quality

Billions of our products are trusted worldwide, thanks to our innovative design, engineering excellence and rigorous testing.

Over 60 years of innovation

Improving performance and efficiency by transforming the way pipe and tube connections are made.

Resources

Here are some helpful resources. All our other resources including install guides, brochures, data sheets, case studies and videos can be found in the resource centre.

Watch our Time-Trial: Copper vs Plastic Push-fit

With JG Speedfit you can make reliable connections over four times faster than soldering.

Download our Plumbing and Heating Product Guide

Find out about our wide range of innovative products designed to make your life easier.

Download our Plumbing and Heating Technical Guide

Get technical information and best practice advice on installing JG Speedfit.

FAQs

No, there is no CE mark guidance for pipe work.

See table below for different applications and maximum temperatures and pressures:

Application | Usual working temperature °c | Maximum working temperature °c | Maximum working pressure, bar |

|---|---|---|---|

Cold water | 20 | 20 | 12.5 |

Central heating | 82 | 105, short term malfunction at 114 | 3 |

Hot water | 65 | 95 | 6 |

NB: High temperatures: Speedfit fittings suitable for central heating systems can withstand temperatures up to 114°C intermittently for short periods. Speedfit fittings shown as not suitable for central heating systems are used primarily on the domestic hot and cold water systems with temperatures of up to 65°C.

Speedfit is a reliable plastic push-fit plumbing and heating system that is fast and simple to install, without the need for tools. As well as being a complete plumbing and heating system (pipes, fittings and valves), Speedfit products can also be used separately for repair, maintenance and improvement work.

Speedfit is suitable for cold water mains (indirect and direct), central heating and hot water systems (including unvented cylinders). Some Speedfit valves and tap connectors are only suitable for hot water systems, so always check the product packaging or manufacturer’s website before installation.

Yes, as long as the collets remain sharp and O-Rings are inspected for cleanliness and the fitting is in good working order it can be reused.

No, tools are not required for JG Speedfit fittings. For the Twist & Lock range, turn the screwcap on the fitting to the unlocked position. Push the collet square against the face of the fitting using your fingers. With the collet held in position, the pipe can be removed.

For standard fittings, push the collet square against the face of the fitting. With the collet held in position, the pipe can be removed.

Yes, Speedfit fittings and pipe comply with the Water Regulations Advisory Scheme (WRAS).

Stay Connected!

Get the latest blog posts directly to your inbox including best practice, industry trends and practical hints and tips.

Case studies

Discover how our JG Speedfit solutions are transforming productivity and efficiency with our latest case studies. All of our other case studies can be found in our resource centre.

Chobham Manor

Find out how Chobham Manor used our products to overcome installation challenges and reduce overall water consumption.

Littleport

Learn how Littleport used our tool-free push-fit connections to ensure the project was delivered on time and to a high-quality standard.

Bilton Farm

See how Bilton Farm used our plumbing and heating system to speed up installation and provide reliable and safe water flow.

Speak to one of our experts to find out more