JG Speedfit fittings

Fast, simple and reliable push-fit fittings for plumbing and heating.

Discover our range

JG Speedfit’s extensive range of push-fit fittings make life easier by creating fast, simple and secure connections.

Using a unique blend of push-fit and multi-seal technology, reliable connections can be made in seconds without the need for tools or hot works. Our fittings are also fully demountable making system alterations and extensions quick and easy too. Suitable for hot and cold water and central heating systems, our push-fit fittings are available in a range of sizes and come with a guarantee for extra peace of mind.

Push-fit Plastic Fittings

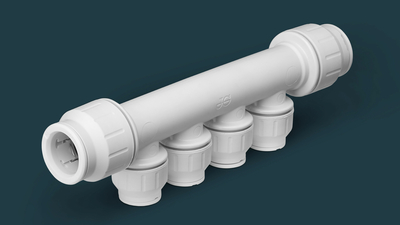

Push-fit Plumbing Manifolds

Push-fit Brass Fittings

Transform productivity and efficiency, without compromising quality

Find a JG Speedfit stockist near you

Benefits of JG Speedfit fittings

Our extensive range of high quality push-fit fittings offer both time and labour-saving benefits, especially when compared to traditional methods.

High performance leakproof connections

Install, demount and refit in seconds without tools

Safer and cleaner with no hot works, flux or glue

Less labour-intensive, especially in tight spaces

Non-toxic, resists corrosion and scale build-up

Compatible with plastic or copper pipe

Push-fit fittings FAQs

The Superseal Insert (STS) has a dual O-Ring, which provides a greater seal than a standard Insert. When combined with a Speedfit fitting, both the fitting and Superseal insert form a unique multi seal.

The Standard Insert (TSM) does not have an O-Ring and therefore allows more pipe into the fitting, making it suitable when connecting Speedfit pipe to compression fittings.

Yes, they are suitable for this application.

Yes, however, the insert should be selected based on the fitting type. If using JG Speedfit Polybutylene Layflat, or PEX pipe with JG Speedfit Twist & Lock fittings we recommend using the JG Speedfit Superseal Insert which offers a multiseal connection. If installing the pipe with standard-type JG Speedfit fittings, then a Standard Insert is required. Both inserts ensure a tight leak-proof connection.

Speedfit fittings can be used with plastic barrier pipe or copper pipe. Speedfit cannot be used with stainless steel pipe.

Yes, either a Speedfit standard or Superseal insert is required to ensure that the ends of the plastic pipe are kept nice and round, and to minimise any loss of shape which can occur when cutting the pipe.

When connecting to copper pipe, the minimum distance to make a solder connection on the copper pipe inserted into a Speedfit fitting is 450mm (18 inches). To prevent damage, you must ensure any residual flux solder does not come into contact with the fitting. A pipe insert is not required when connecting Speedfit fittings to copper pipe.

Yes, but only if the pipe and fittings are compatible. Compression fittings with a short tube stop depth or brass olives should not be used with Speedfit pipes. Use a standard pipe insert (TSM) and follow the instructions of the compression fitting manufacturer when connecting to plastic pipework. The connection should not need more than 2 full turns after the olive has gripped the pipe. JG Speedfit recommends using soft copper olives, always ensure the nut and olive are in place before inserting the pipe insert.

We have been using JG Speedfit across our sites for many years and find it to be a more reliable and better quality fitting than its competitors, especially the locking feature which is secure and also easy to demount when required.